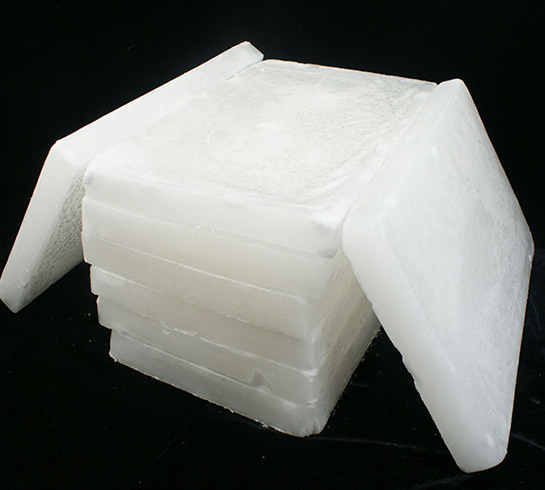

Semi Refined Paraffın wax

What is Semi Refined Paraffın wax ?

Semi-refined paraffin wax, also known as slack wax, is a type of wax that is derived from the slack or residue of the crude oil refining process. It is a yellowish-brown, soft, and sticky substance that contains oil and other impurities.

Semi-refined paraffin wax has a lower melting point and oil content than fully refined paraffin wax. It is typically used in industrial applications where a high degree of purity is not required, such as in the manufacturing of matches, rubber products, and asphalt. It is also used as a lubricant in various industrial processes.

Semi-refined paraffin wax is produced by partially refining crude oil through a process of solvent deoiling or solvent dewaxing. The resulting wax is then filtered and purified to remove some of the impurities, but not to the same degree as fully refined paraffin wax. The melting point of semi-refined paraffin wax ranges from 45°C to 65°C, depending on the specific grade and quality.

Semi-refined paraffin wax is less expensive than fully refined paraffin wax and is a suitable option for applications where high purity is not critical. However, it may not be suitable for use in products that require a stable and consistent texture and appearance, such as candles or cosmetics.

Quality of Semi Refined Paraffın wax

The quality of semi-refined paraffin wax can vary depending on the specific grade and the processing methods used. Generally, semi-refined paraffin wax is considered to be of lower quality than fully refined paraffin wax due to its higher oil content and impurities.

Semi-refined paraffin wax typically contains more oil and other impurities than fully refined paraffin wax, which can affect its physical properties and performance in different applications. For example, semi-refined paraffin wax may have a softer texture and lower melting point than fully refined paraffin wax, which can make it less suitable for certain applications.

The quality of semi-refined paraffin wax can be improved through additional processing and refining steps, such as filtration, bleaching, and deodorizing. However, these processes can also increase the cost of the wax and may not be necessary for certain industrial applications.

Overall, the quality of semi-refined paraffin wax is generally considered to be lower than that of fully refined paraffin wax due to its higher impurity content. However, it remains a popular and cost-effective option for industrial applications where high purity is not critical.

History of Semi Refined Paraffın wax

The history of semi-refined paraffin wax can be traced back to the late 19th century when crude oil was first discovered and commercialized. Initially, the crude oil was used primarily as a fuel for lamps and heating, but as its other properties were discovered, it began to be used in other industries as well.

The production of semi-refined paraffin wax began in the early 20th century as a by-product of the crude oil refining process. The wax was originally considered a waste product and was often burned as fuel or disposed of in other ways.

However, as the demand for wax increased in various industries, including the textile, rubber, and paper industries, the production of semi-refined paraffin wax became more widespread. The wax was initially used primarily in industrial applications, such as asphalting and waterproofing, but it soon found other uses as well.

During World War II, the demand for semi-refined paraffin wax increased as it was used in the production of explosives and other military equipment. After the war, the demand for the wax continued to increase as it was used in a variety of consumer products, including candles, cosmetics, and food.

Today, semi-refined paraffin wax remains an important industrial material, used in a variety of applications where high purity is not required. While it may not be as widely used as fully refined paraffin wax, it remains an important and cost-effective option for many industries.

Usages of Semi Refined Paraffın wax

Semi-refined paraffin wax has a variety of industrial applications due to its unique properties. Some common usages of semi-refined paraffin wax include:

Candle making: Semi-refined paraffin wax is often used in the production of candles due to its ability to hold fragrance and color.

Coatings and sealants: The wax can be used as a coating or sealant for various surfaces, including concrete, paper, and textiles.

Adhesives: Semi-refined paraffin wax can be used in the production of adhesives due to its tackiness and ability to bond to different surfaces.

Waterproofing: The wax can be used to waterproof various materials, including fabrics, leather, and paper.

Cosmetics: Semi-refined paraffin wax can be found in various cosmetic products, such as lipsticks, lip balms, and creams.

Packaging: The wax can be used as a protective coating for food packaging, such as cheese and meat.

Textiles: Semi-refined paraffin wax is used as a sizing material in the textile industry to improve the smoothness and durability of fabrics.

Packing of Semi Refined Paraffın wax

Semi-refined paraffin wax is typically packed in different types of packaging materials, depending on the specific needs of the buyer and the transportation method. Some common types of packaging for semi-refined paraffin wax include:

Cartons: Semi-refined paraffin wax is often packed in cartons made of corrugated paper or cardboard. Cartons are typically used for smaller quantities of wax and are easy to handle.

Bags: Semi-refined paraffin wax can be packed in bags made of plastic or paper. This type of packaging is commonly used for larger quantities of wax, and the bags can be stacked on pallets for easy transportation.

Drums: Semi-refined paraffin wax can be packed in steel drums or plastic drums for easy transportation. Drums typically hold larger quantities of wax and can be sealed to prevent moisture and contaminants from entering.

Bulk tanks: For very large quantities of wax, semi-refined paraffin wax can be transported in bulk tanks. These tanks are typically made of stainless steel and can hold several tons of wax.

Prices of Semi Refined Paraffın wax

The prices of semi-refined paraffin wax can vary depending on several factors, such as the quality, quantity, and location of the supplier. Generally speaking, semi-refined paraffin wax is less expensive than fully refined paraffin wax, but more expensive than crude paraffin wax.

As of my knowledge cutoff date of September 2021, the average price of semi-refined paraffin wax ranged from $800 to $1200 per ton, depending on the quality and quantity ordered. However, it's important to note that prices are subject to change over time and may vary depending on market conditions.

It's recommended that buyers obtain quotes from multiple suppliers to compare prices and ensure they are getting a fair price for their desired quality and quantity of semi-refined paraffin wax.

Delivery time and Readiness of Semi Refined Paraffın wax

The delivery time and readiness of semi-refined paraffin wax can vary depending on the specific supplier and the quantity ordered. In general, smaller quantities of semi-refined paraffin wax can be shipped immediately or within a few days, while larger quantities may require more preparation time.

Once the order is confirmed, the supplier will typically prepare the semi-refined paraffin wax for shipment. This may involve melting and filtering the wax to ensure it meets the desired quality standards. The wax is then packaged and prepared for shipping.

The delivery time of semi-refined paraffin wax can also vary depending on the location of the supplier and the buyer. International shipping may take longer than domestic shipping, and additional time may be required for customs clearance.

Overall, the delivery time and readiness of semi-refined paraffin wax will depend on the specific circumstances of the order. It's important for buyers to communicate their delivery timeline expectations with the supplier to ensure that their needs are met.

Analysis Table of Semi Refined Paraffın wax

| Property | Test Method | Specification |

| Melting Point | ASTM D87 | 58-62°C |

| Oil Content | ASTM D721 | 1.5-3.5% |

| Color | ASTM D1500 | > +28 Saybolt |

| Needle Penetration | ASTM D1321 | 15-25 (1/10mm) |

| Congealing Point | ASTM D938 | 54-58°C |

| Density @ 25°C | ASTM D938 | 0.88-0.92 g/cm³ |

| Flash Point (COC) | ASTM D92 | > 200°C |

| Viscosity @ 100°C | ASTM D445 | 3.0-4.5 cSt |

| Acid Value | ASTM D664 | < 0.5 mg KOH/g |

| Refractive Index | ASTM D1747 | 1.443-1.459 |

| Penetration @ 25°C | ASTM D1321 | 20-30 (1/10mm) |

| Odor | Internal Method | Odorless |